Technical terms of quality management: H

HACCP

Hazard Analysis and Critical Control Points. HACCP is a systematic tool in the framework of food safety management. It is used to define preventive measures and consequently to avoid dangers in association with food (e.g., illnesses). HACCP roughly means the analysis of health hazards and the determination of critical points.

HALO effect

When assessing a person (“first impression“) one unconsciously looks for the other person‘s most striking characteristic and then generalizes this feature or trait.

Hardware

Material product whose quantity represents a countable characteristic. (On the basis of ISO 9000:2015)

Heijunka

Harmonization of the production flow (process smoothing). Heijunka (a term that originated in Japan) can be seen as a part of just-in-time thinking. The production flow should be harmonized so that the production is leveled out in terms of quantity, thereby avoiding queues and waiting times.

HGB

Handelsgesetzbuch [German Commercial Code].

High level structure

(Future) identical clause structure of all management system standards with partly identical text passages in the clauses dealing with requirements. This high level structure is aimed at making better use of synergies between different disciplines. The management system standards differ with respect to their scope and objectives.

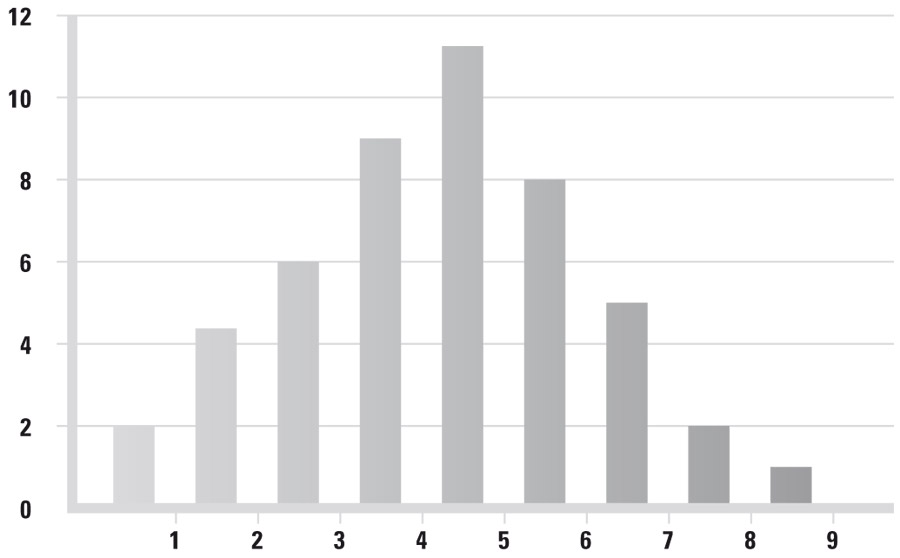

Histogram

The histogram is a quality tool (Q7) used for a graphical representation of the frequency distributions of data. The (quantitative) data here are divided into classes.

HLS

Hoshin process

House of Quality

See Quality Function Deployment.

Hypothesis

See also: Hypothesis test.

Hypotheses are defined in the respective hypothesis test. Here, hypotheses represent the translation of a practical question into a statistical question. In this way, a problem from the “real world“ is described in terms that are suitable for scientific investigations and tests.

Hypothesis statements are essentially limited to a comparison of mean values and/or variances. After carrying out statistical procedures (see Hypothesis test), the hypothesis that was made is either accepted or rejected.

Here it is necessary to distinguish between the following concepts:

Null hypothesis (Ho)

Hypothesis that there are no differences between the groups.

Example: Supplier A and B have the same average delivery times.

Alternative hypothesis (Ha) (also called the working hypothesis)

Hypothesis that there are differences.

Example: Supplier A and B have different average delivery times.

Alpha risk

Maximum risk that the examining party faces if it rejects the null hypothesis Ho although it is true.

Beta risk

Risk that Ha is rejected and Ho is accepted, although there really is a difference.

Hypothesis test

See also Hypothesis.

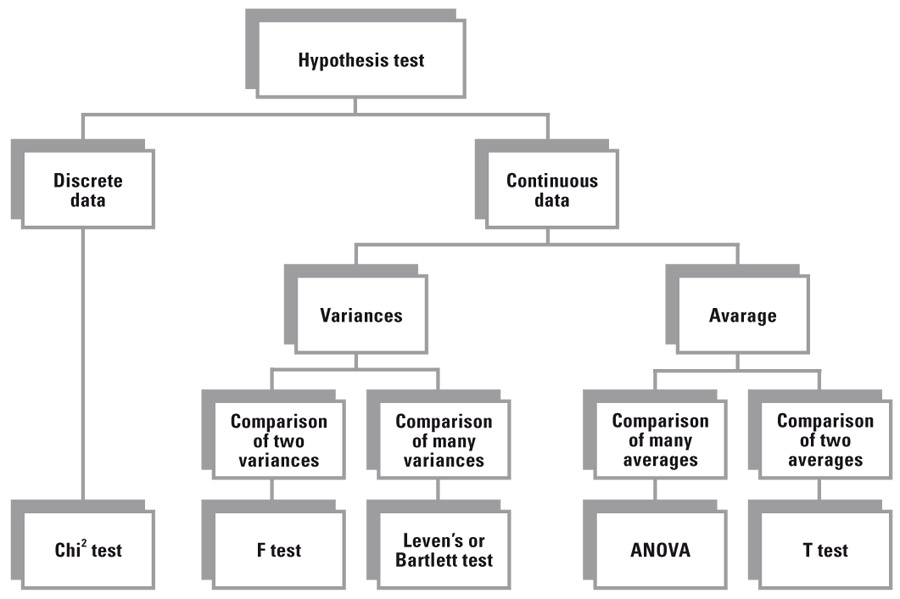

Hypothesis tests are statistical procedures to confirm or refute assumptions that have been made regarding differences between groups of measured samples. They can be used both to compare average values and variances.

The following diagram shows a classification of the various hypothesis tests: