Technical terms of quality management: F

Factorial experiment

See also DoE.

In statistical experimental design (DoE, Design of Experiments) there is a definition of whether a full factorial or fractional factorial test plan will be set up and conducted.

Full factorial – all defined settings of the factors are actually carried out.

Fractional factorial – only certain settings of the factors are actually carried out.

The benefit of a fractional factorial procedure is the more economical performance of the tests because not all combinations of the factors have to be performed.

Factual approach

The factual approach to decision-making is one of the eight quality management principles (see Quality management principles).

FAI

Failure Mode and Effects Analysis

Method for risk analysis: The potential causes of failures, possible types of failures and expected effects of failures in a system and its element are analyzed. In the next step, a risk assessment is made and actions are defined for prioritized risks. After working off the actions defined in the first assessment, a second risk assessment is made in order to determine if the actions are productive. The risks are calculated and rated with the help of the risk priority number. NASA developed this method in the mid-1960s. The following types of FMEA are possible:

System FMEA: This method concentrates on the functional observation of a product from the user‘s point of view.

Design FMEA: This method constitutes a procedure for reviewing the design. The goal is to discover and remedy failures that arise during a product‘s development in the development phase.

Process FMEA: This method is used to examine the individual steps in the production process. The objectives of the examination can be either technical or procedural-organizational processes.

Fault

A unit’s lack of fulfillment, nonconforming fulfillment or incomplete fulfillment of a required function. (On the basis of DIN 40041:1990)

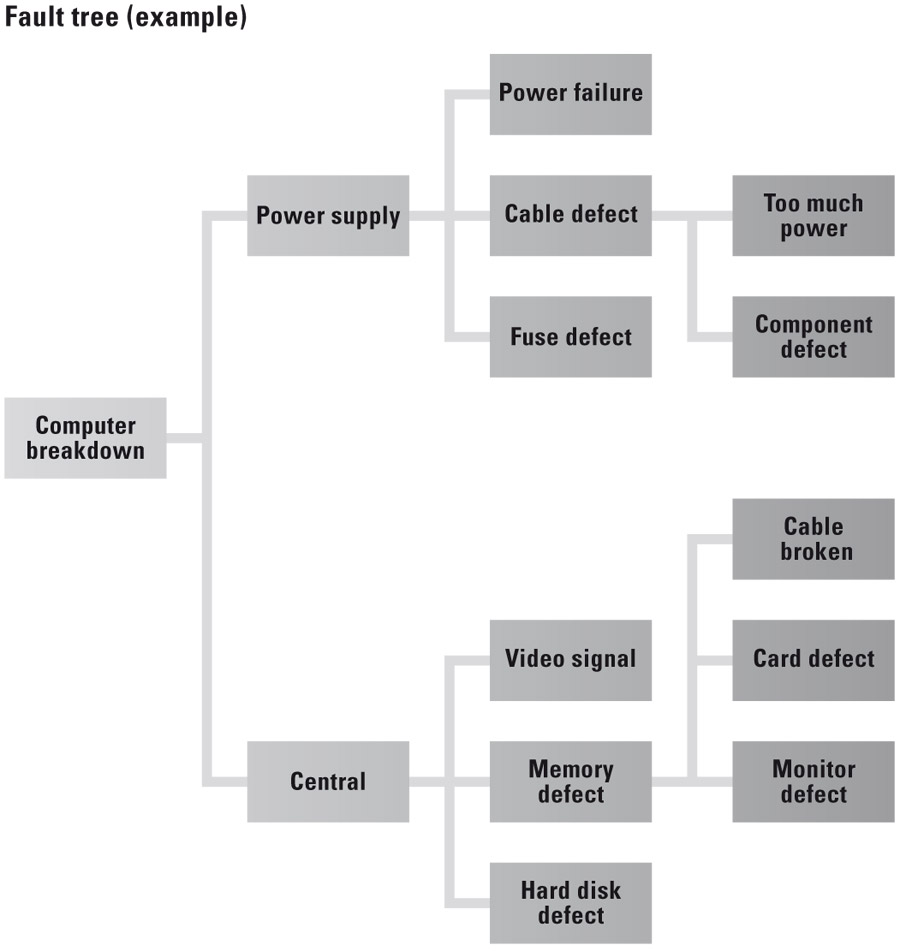

Fault tree analysis

Fault tree analysis is a procedure that allows probabilities to be estimated. This analysis is most commonly used in systems that are critical to safety or that are highly available. The fault tree is created by means of a system analysis that is conducted beforehand. Combinations of faults are also taken into consideration. This method requires precise knowledge of the system analysis and probability calculation.)

FDA

U.S. Food and Drug Administration, Maryland USA. www.fda.gov

Feigenbaum

The American Armand V. Feigenbaum (born in 1922) is one of the pioneers and significant figures in quality science. His core activities were “Total Quality Control“ and “Simultaneous Engineering“.

FIEV

Fédération des Industries des Equipements pour Véhicules. Organization of the French automotive supply industry. www.fiev.fr

FIFO

FIFO stands for “first-in – first-out“ and describes a stock management system that optimizes the inventory turnover times and inventory turnover. Goods that were put into storage first are also taken out of storage first.

Final inspection

The last of the quality inspections that is conducted before a unit is handed over to the customer or client.

Finding

Evaluation of an audit finding.

Example: A required procedure of a standard‘s requirement is, to some extent, not fulfilled or a required procedure is installed in the company but not yet fully implemented. Individual requirements of the sub points are predominantly not fulfilled. This includes both a lack of planning and a lack of effective implementation. In any case, a finding makes a corrective action necessary, while a certificate can be issued or maintained, however.

First article

Sample that is, without exception, manufactured with equipment and procedures (under the associated general conditions) that are planned for series manufacturing. The first article allows verification that the quality requirement on the offered product can be fulfilled, as far as this takes place under the series manufacturing conditions. The terms “initial sample“, “quality specimen“, “type sample“ are used synonymously. (On the basis of DIN 55350-15)

First Article Inspection

Inspection of a first article in the framework of a sample inspection. (On the basis of DIN 55350-15)

First inspection

The first in a series of planned or authorized quality inspections. (On the basis of DIN 55350-17)

First pass rate

First-party audit

Internal audits that are carried out by the organization itself (also “Self-assessment“), for example, for a management review or as the basis for the company‘s declaration of conformity. (On the basis of ISO 9000:2015)

Fishbone diagram

Fitness for use

Usability of a commodity for its use as intended. The suitability is based on objective and subjective functional properties. The evaluation is derived from the individual needs. (On the basis of DIN 55350-11)

Juran defines quality as “fitness for use“ in the eye of the customer because the assessment of quality derives from the customer‘s individual needs and expectations (customer-focused quality term).

Fixed costs

Term for the (total) costs that do not change with the capacity utilization level. These are also called time-related costs.

Flowchart

Illustration of procedures and depiction of processes and activities Flowchart

Depiction of all processes in a company. The chart illustrates the most important elements in a process: Tasks, work steps, activities, material movements, decisions.

Visualization of the workflows during manufacturing or sale of a product, the material flow or information flows.

FMEA

See Failure Mode and Effects Analysis.

FMECA

Failure Mode, Effect and Criticality Analysis. The US military developed the FMEA in 1949 under the name FMECA. It was used for the systematic development of reliability with examination of system and equipment failures.

Follow-up audit

A follow-up audit is conducted when one or more (critical) deviations (nonconformities) occur in the audit that require a longer time for correction. The effective realization of the corrective actions and consequently elimination of the deviation(s) can be proven in the follow-up audit, for example. As a result a certificate can be issued.

FQS

Forschungsgemeinschaft für Qualität e.V., Frankfurt. www.fqs.de

Frequency

Number indicating how often a certain result or event occurs.

Frequency distribution

Distribution of actual values.

Note: The frequency distribution for one, two or more characteristics is called one-dimensional (univariate), two-dimension (bivariate) or multi-dimensional (multivariate).

(DGQ Volume 11-04:2009)